Start precision CNC machining service since 2000

Provid precision CNC machining stainless steel, aluminum components for medical, electronics field industry.

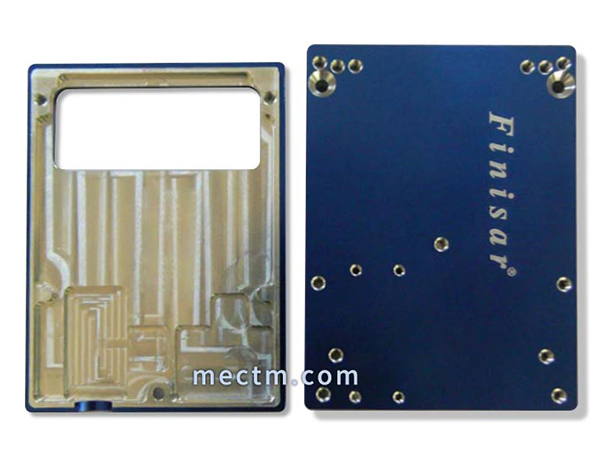

Start supporting aluminum housing for optical communication, fiber laser industry

since 2008

Provid precision and critical aluminum housing, heatsink,block, plate, handpieces, micro hole Pinhole parts. Because of our high and consistent quality (including cosmetic finish), short lead time (usually about 2-3 weeks), small lot acceptable, we have obtain more than 25 customers in the optic and fiber industry, some of them are the leaders in their field such as Finisar.

Start supporting marine parts since 2010, designed and found a special finish for clear aluminum marine parts obtained long durability

How many years they can standing in the sun exposure and salt-water marine environment is hard to track, but in the conducted test:

Ultraviolet testing: more than 1000 hours (general market standards only 72hours).

Salt Fog testing: more than 1000 hours (general market standards only 96,192 hours).

Compare to the clear anodize hard finish, it have competitive cost.

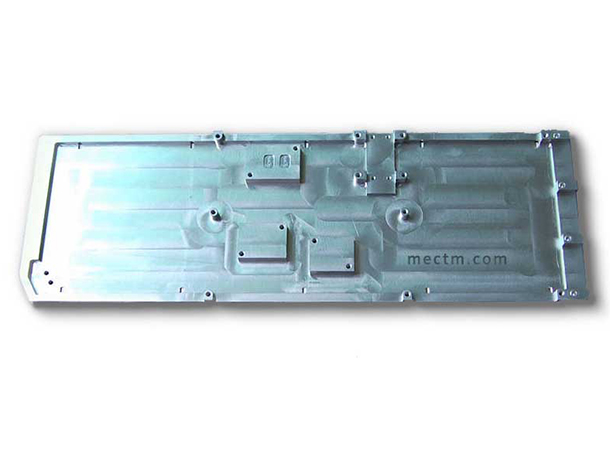

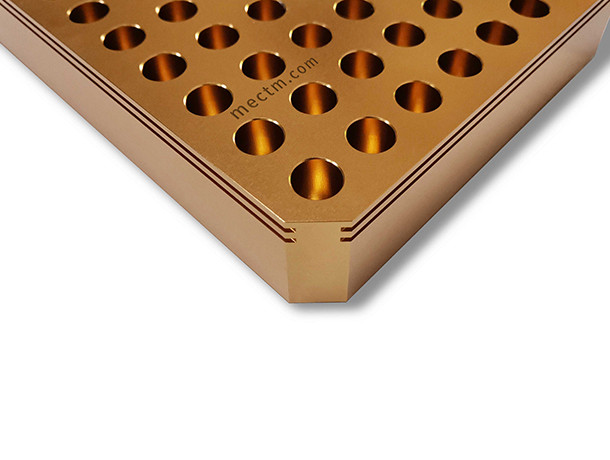

Start supporting aluminum laboratory workstation since 2011

This kind part usually need milling from solid aluminum with many pieces precision and deep holes at the meantime require a mirror mill finish (no tool marks visiable) for whole part, after anodize process, no scratches no dents no discoloration visiable.

How to vertical mill 112mm height side surface and get a mirror mill finish?

We achieve it.

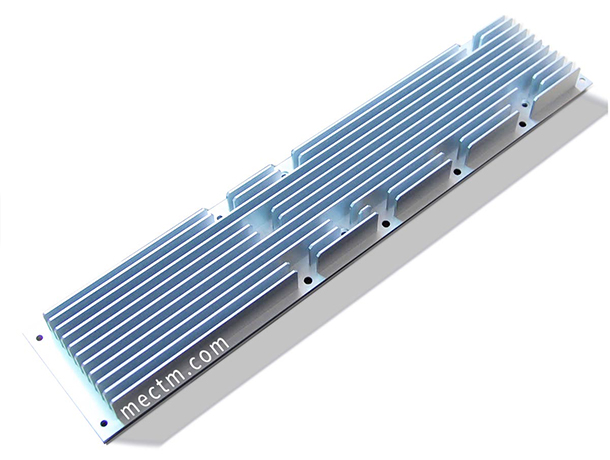

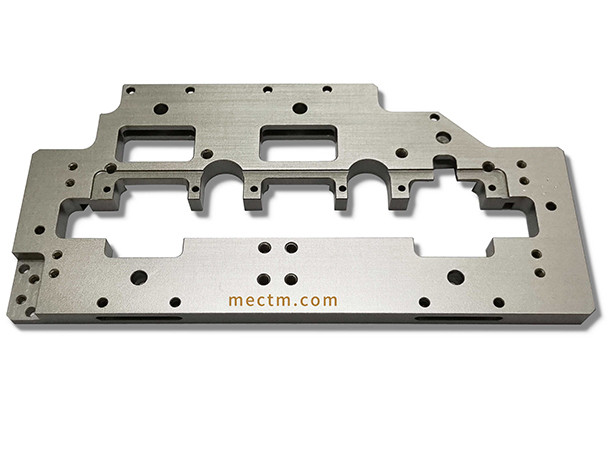

Start supporting aluminum RF microwave housing for telecommunication industry since 2012

This kind precision part usually milled from solid aluminum, much big and high, need silver or gold plating finish.

To name just a few, there are many precision parts customized in our factory for various industries all these years. We have much effient experience for your precision customized parts.